Cut-Out Machine

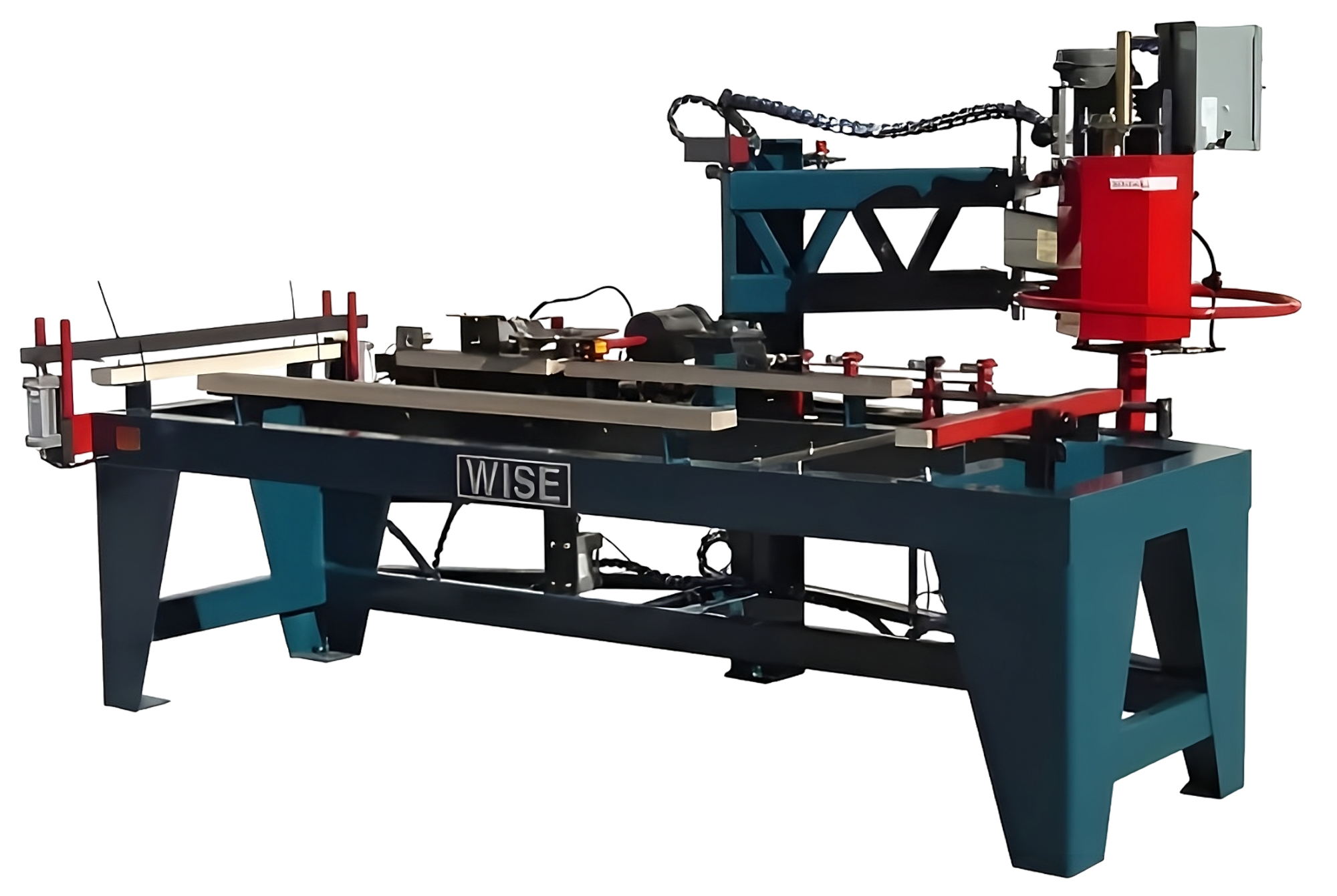

Wise 7000 Door Lite Cut-Out Machine

Description

The WISE 7000 Door Lite Cutter is designed to maintain consistent high quality and fast production in this critical millwork operation. The WISE 7000 can cut various lite sizes in a simple operation with minimal effort and is a heavy duty, versatile machine that allows a single operator to customize steel, wood or fiberglass doors quickly and efficiently.h-volume door manufacturers looking to optimize their production line, reduce errors, and maintain high-quality standards in their prehung door assembly process.

Key Features

-

Key Features

- Auto Bore and Mortising of the Latch and Deadbolt

- Lock and Deadbolt Boring

- Auto Backset

- Quick Changeover for Various Door Lite Sizes

- Permanent Bore Template with Replaceable Inserts

- Radial Cutting

- Quick Change Stop System

Options Available

-

Options Available

- Steel Edge Prep

- Dust Collection System

- 4-Bag Stand Alone Vacuum Unit

Specifications

Specifications

- Doors

- Steel, Wood and Fiberglass Doors

- Length: 6-8 to 8-0

- Width: 1-4 to 3-0

- Maximum Door Lite Patterns

- 30” x 60”

- 24” x 66”

- Lock & Deadbolt Bore Sizes

- 1-1/2” | 1-5/8” | 2-1/8”

- Backsets

- 2-3/8” | 2-3/4”

- Faceplates

- Length: 2-1/4” to 2-3/4”

- Width: 1” to 1-1/8”

Air Requirements

Air Requirements

1 cfm @ 90 psi – 3/4” Feed Line

Electrical Requirements

230v, 3 Phase, 30 Amp, 60 HZ and

120v, 1 Phase, 15 Amp, 60 HZ

Electrical Requirements

Electrical Requirements

None

Dimensions & Weight

Dimensions

8′ Long x 5′ Wide x 6′ Tall

Weight

1800 lbs

Optional Machines Available

Optional Machines Available

Wise 1500 Strike Jamb Processing Machine

Wise 1525A Automatic Hinge Jamb Machine

Wise 3200 Flat Jamb Stop Stitcher

Wise 3400 Split Jamb Stitcher

Financing Available

Financing Available

Click Here for Payment Options

Why Choose the Wise 7000

In the ever-evolving world of prehung door manufacturing, staying ahead of the competition means embracing cutting-edge technology that enhances efficiency, quality, and versatility. The Wise 7000 Door Lite Cut-Out Machine has emerged as a game-changer in the industry, offering a range of benefits that can significantly improve your manufacturing process. Let’s explore the top five pros of incorporating this innovative machine into your production line.

- Unparalleled Precision and Consistency

The hallmark of a high-quality prehung door is precision, especially when it comes to door lite cutouts. The Wise 7000 Door Lite Cut-Out Machine excels in this area, delivering unmatched accuracy with every cut. Utilizing advanced CNC technology, this machine ensures that each cutout is executed with pinpoint precision, meeting exact specifications time after time.

This level of consistency is crucial for several reasons. Firstly, it guarantees that door lites fit perfectly, enhancing the overall quality and appearance of the final product. Secondly, precise cutouts contribute to better energy efficiency and weatherproofing, as they allow for proper sealing around the glass insert. Lastly, the consistency in cutouts streamlines the assembly process, reducing the need for adjustments and rework.

By eliminating human error and variability, the Wise 7000 not only improves the quality of your products but also boosts customer satisfaction and reduces the likelihood of returns or complaints.

- Increased Productivity and Efficiency

In the fast-paced world of door manufacturing, time is money. The Wise 7000 Door Lite Cut-Out Machine significantly increases productivity by automating a process that traditionally required manual labor and multiple steps. With its rapid cutting capabilities, this machine can process doors at a speed that far surpasses manual methods.

The efficiency gains are not just in speed, but also in workflow optimization. The Wise 7000 can be seamlessly integrated into your existing production line, creating a smooth, continuous process from door blank to finished product. This integration minimizes handling time and reduces the risk of damage during production.

Moreover, the machine’s ability to handle various door sizes and styles without lengthy setup changes means you can switch between different product lines quickly and efficiently. This flexibility allows you to respond more rapidly to customer demands and market trends, giving you a competitive edge in the industry.

- Versatility in Design Options

One of the most significant advantages of the Wise 7000 Door Lite Cut-Out Machine is its versatility. This machine is capable of creating a wide range of cutout shapes and sizes, from standard rectangular openings to complex custom designs. This flexibility opens up new possibilities for product offerings and allows manufacturers to cater to diverse customer preferences.

Whether you’re producing doors for residential, commercial, or architectural applications, the Wise 7000 can handle it all. Its programmable interface allows for easy input of new designs, enabling you to quickly adapt to changing market demands or fulfill custom orders without the need for additional tooling or equipment.

This versatility not only expands your product range but also positions your company as a go-to solution for customers seeking unique or specialized door designs.

- Enhanced Safety and Reduced Labor Costs

Safety is paramount in any manufacturing environment, and the Wise 7000 Door Lite Cut-Out Machine contributes significantly to a safer workplace. By automating the cutting process, it reduces the need for manual handling of heavy doors and exposure to sharp cutting tools, minimizing the risk of workplace injuries.

The machine’s enclosed design and safety features protect operators from debris and noise, creating a more comfortable and secure working environment. This focus on safety can lead to reduced insurance costs and improved employee satisfaction and retention.

Furthermore, by automating a labor-intensive process, the Wise 7000 allows you to optimize your workforce. Employees previously engaged in manual cutting can be reassigned to other value-adding tasks, potentially reducing labor costs while increasing overall productivity.

- Improved Material Utilization and Reduced Waste

In an era where sustainability and cost-efficiency are increasingly important, the Wise 7000 Door Lite Cut-Out Machine shines by optimizing material usage and reducing waste. Its precise cutting capabilities mean that errors and miscuts are virtually eliminated, reducing the number of scrapped doors and wasted materials.

The machine’s software can be programmed to optimize cutout patterns, maximizing the use of each door blank and minimizing offcuts. This not only reduces material costs but also aligns with environmentally conscious manufacturing practices, potentially opening up new markets and customer bases that prioritize sustainability.

Additionally, the reduced waste and improved efficiency contribute to a leaner, more cost-effective operation, allowing you to maintain competitive pricing without sacrificing quality or profitability.

In conclusion, the Wise 7000 Door Lite Cut-Out Machine offers a compelling array of benefits for prehung door manufacturers. From unparalleled precision and increased productivity to enhanced design versatility, improved safety, and optimized material usage, this machine is a valuable investment for any company looking to stay at the forefront of the industry. By embracing this technology, manufacturers can not only improve their current operations but also position themselves for future growth and success in an increasingly competitive market.

Why Choose the Wise 7000 Door Lite Cut-Out Machine?

In the ever-evolving world of prehung door manufacturing, staying ahead of the competition means embracing cutting-edge technology that enhances efficiency, quality, and versatility. The Wise 7000 Door Lite Cut-Out Machine has emerged as a game-changer in the industry, offering a range of benefits that can significantly improve your manufacturing process. Let’s explore the top five pros of incorporating this innovative machine into your production line.