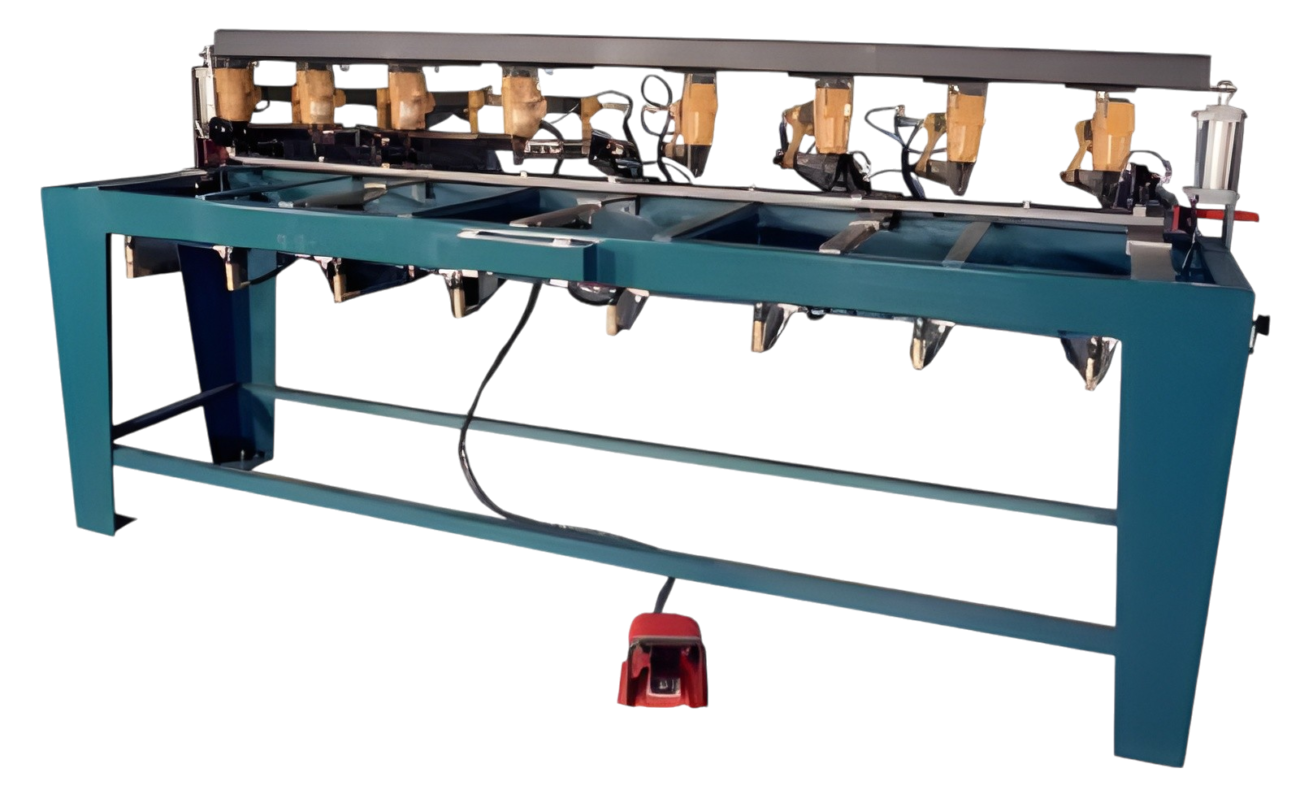

WISE 3200 Stop Attacher : Top 3 Benefits in the Prehung Door Manufacturing Industry

The prehung door manufacturing industry thrives on precision, speed, and efficiency. Each step in the process, from cutting and assembling to final finishing, requires specialized equipment to ensure consistent, high-quality results. One such piece of equipment is the WISE 3200 Stop Attacher. Designed specifically for prehung door production, this machine offers significant advantages that can transform the efficiency and output of a manufacturing operation. Here are the top three benefits of using a WISE 3200 Stop Attacher in the prehung door manufacturing industry.

1. Streamlined Efficiency and Faster Production

In prehung door manufacturing, attaching the door stop—the piece that prevents the door from swinging through the frame—is a critical but time-consuming task. Traditionally, this step requires careful manual alignment and fastening, which can slow down production. The WISE 3200 Stop Attacher revolutionizes this process by automating the attachment of the door stop, ensuring that each stop is precisely positioned and securely fastened.

The automation provided by the WISE 3200 dramatically increases production speed. With the ability to attach stops quickly and accurately, manufacturers can reduce the time spent on each door, allowing for higher throughput and more efficient use of labor. This streamlined process leads to faster completion of orders, helping manufacturers meet tight deadlines and fulfill large-scale projects without sacrificing quality.

Additionally, the WISE 3200’s design minimizes the need for manual adjustments, meaning operators can focus on maintaining overall workflow rather than troubleshooting individual stops. This consistency in production not only saves time but also reduces the risk of errors, ensuring that every prehung door meets the required specifications.

2. Consistent Quality and Precision

In the prehung door industry, consistency is key. Even minor deviations in the positioning of the door stop can affect the functionality of the door, leading to customer dissatisfaction and potential callbacks. The WISE 3200 Stop Attacher is engineered to provide precise and consistent results with every application, ensuring that each stop is attached in exactly the right position, time after time.

This level of precision is crucial for maintaining the integrity of the prehung door assembly. The WISE 3200 uses advanced technology to ensure that the stops are aligned perfectly with the door frame, eliminating the possibility of misalignment that can occur with manual attachment. This results in doors that close properly, with no gaps or misfits, contributing to a higher-quality finished product.

By automating the attachment process, the WISE 3200 also reduces the potential for human error. With manual methods, variations in operator skill and attention to detail can lead to inconsistencies in the final product. The WISE 3200 eliminates this variability, ensuring that every door produced meets the same high standards. This consistency not only enhances the reputation of the manufacturer but also reduces the likelihood of costly returns or warranty claims.

3. Reduced Labor Costs and Improved Worker Safety

Labor costs are a significant factor in the manufacturing industry, and any opportunity to reduce manual labor without sacrificing quality can lead to substantial cost savings. The WISE 3200 Stop Attacher offers an excellent solution by automating the stop attachment process, allowing manufacturers to reduce the number of labor hours required for each door.

With the WISE 3200, a single operator can manage the stop attachment process for multiple doors simultaneously, drastically reducing the need for manual labor. This reduction in labor not only cuts costs but also allows manufacturers to allocate their workforce to other critical areas of production, improving overall productivity.

Furthermore, automation enhances worker safety by minimizing the need for repetitive manual tasks, which can lead to strain injuries over time. The WISE 3200’s automated system reduces the amount of physical labor required, lowering the risk of workplace injuries associated with repetitive motions or improper handling of tools. By prioritizing safety, manufacturers can create a more positive work environment and reduce costs related to injury-related downtime and workers’ compensation claims.

Conclusion

The WISE 3200 Stop Attacher is a game-changer in the prehung door manufacturing industry. By streamlining the stop attachment process, it significantly boosts production efficiency, ensures consistent quality, and reduces labor costs while improving worker safety. For manufacturers looking to optimize their operations and maintain a competitive edge, investing in the WISE 3200 can lead to tangible benefits in both productivity and product quality. With its ability to enhance every aspect of the stop attachment process, the WISE 3200 is an invaluable tool for any prehung door manufacturing operation looking to stay ahead in today’s fast-paced market.